BOMBING

The component to be tested is placed into a pressurized chamber with helium for some time. At the end of it the component is taken out and put into a reading room (directly connected to the mass spectrometer) where any leaks flowing from the infiltrations happened during the period of pressurization.

This technique is applied to all the components which cannot be pressurized or evacuated, which require an high test sensitivity and a quantitative measure of the leak.

Main tested products

- Valves

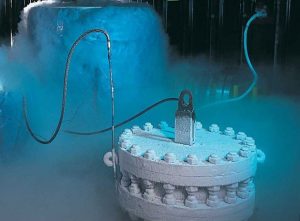

- Valves with cryogenic test

- Tanks and exchangers

- Cryogenic tanks and movable tanks

- Chemical reactors – processing columns

- Thermocouples and sensors

- Storage lines

- Underground gas lines

- Industrial plants

- Gas transport ships